|

|

305 SBC

Sept 10, 2005 11:03:57 GMT -5

Post by kringold on Sept 10, 2005 11:03:57 GMT -5

I pulled the starter yesterday and ran it to Schuck's and had it tested. They ran the test twice and it worked fine both times. So I took it home re-installed it, what a pain, and tried starting it. Again I got no dome light or dash lights and no headlights. I turned the key and nothing. I hooked up my charger and I got all my lights. Turned the charger to boost and tried starting it. Now atleast the starter is clicking, but it still isn't starting. I think I'm going to take this NAPA battery back and hopefully they will give me a good one this time. I might pull the alternator too, while I'm at, it and have it tested.

|

|

|

|

305 SBC

Mar 6, 2006 23:31:50 GMT -5

Post by kringold on Mar 6, 2006 23:31:50 GMT -5

Okay I just passed the 1000 mile mark on this rebuild. I've changed the oil and filter twice since. Then it started to tick on the passengers side. So I reset the lash on the suspected cylinder. The tick was still there. So last night I decide to reset the valve lash on all cylinders. The tick was gone but it sure was running like @&*! . So I started over. This time when I turned the key there was one hell of a bang. I have 1/4" pipe plugs in the exhaust manifolds where the old AIR system hooked in. Well it blew one of those out, and I still haven't found that. I replaced that and it wouldn't fire. So a couple of friends dropped by this afternoon and we did it step by step per the shop manual. It still woudn't fire. We then decide to set each cylinder one at a time. I brought the #1 cylinder to TDC after it blew my finger out of the spark plug hole. Set the lash and moved to cynder #3. No compression. So I went and got my compression gauge and it read 0. I went back to #1 cylinder and there was no compression there either. #1 just blew my finger out of the hole! I checked the compression on the rest of the cylinders and they all were 0 except for cylinder #7 which had 138 psi.

Did I blow a head gasket?

|

|

|

|

Post by re-tired on Mar 7, 2006 2:54:05 GMT -5

sounds like you bottomed out lifter(s).look at how many threads are showing on each stud .they should be about same 3-5 threads. watch each valve spring go up /down , again about the same. Make sure rocker studs havent pulled up in head. twirl each push rod see if bent.

|

|

|

|

Post by kringold on Mar 7, 2006 9:23:08 GMT -5

When we set the valve lash, we loosend all the rocker arms until the pushrods spun. Didn't notice any out of round (bent pushrods) then. However I was watching the number of threads and some looked like they had a little more than others. Should I loosen the rocker arms all the way and wait for the lifters to relax, before I set the lash? The studs are stock. Do they move?

|

|

|

|

305 SBC

Mar 7, 2006 10:54:53 GMT -5

Post by re-tired on Mar 7, 2006 10:54:53 GMT -5

Stock rocker studs are pressed in .They should not move. it is ok to have 1-2 thread count difference among the studs. Yes , i would loosen all studs and try again. Do one cyl at a time ,int & exh. bring each cyl to tdc (both valves fully closed) tighten that cyl's rockers while spinning push rods. Go just enough to remove slack then go 1/2 turn more.Repeat for each cyl , following the firing order. There are faster ways but this is safest. If it starts ,loosen one at a tme till it rattles. then go 1/2 -3/4 turn slowly . If eng starts missing , back off till smooth.

|

|

|

|

305 SBC

Mar 7, 2006 11:06:05 GMT -5

Post by kringold on Mar 7, 2006 11:06:05 GMT -5

I started to set them one cylinder at a time. Had finished with #1 and moved to #3 when I found no compression on #3. I checked compression then on #1 and had none. Shouldn't I have? Adjusting them while running is pretty much out of the question. High volume/high pressure oil pump. I could do it if I want to look like I work in a Texas oil field.  The shop manual calls for one full turn down. So should I go back out and finish adjusting each cylinder one by one using one full turn? Will the compression come back then? After I back out the rocker nut, should I wait a couple to let the lifter come back up? Do I NEED to follow the firing order, or can I do one side at a time? |

|

|

|

305 SBC

Mar 7, 2006 14:10:08 GMT -5

Post by re-tired on Mar 7, 2006 14:10:08 GMT -5

I have had better luck at 3/4 turn but you can go full turn if running okThey make clips that go on rockers to control oil spray. they are not that much $.No you dont have to follow firing order ,you will have to turn eng more if you dont. Just make sure cyl is on tdc compression stroke. Give lifter a minute after each change

|

|

|

|

305 SBC

Mar 7, 2006 16:57:47 GMT -5

Post by kringold on Mar 7, 2006 16:57:47 GMT -5

How do you tell if it's on the compression stroke if there is no compression?

|

|

|

|

305 SBC

Mar 7, 2006 17:46:45 GMT -5

Post by re-tired on Mar 7, 2006 17:46:45 GMT -5

You watch your valves . as you turn eng the exh valve will go down (opens) the exh valve will come up (closes) the intake valve does the same. As soon as the int valve closes take a length of clothes hanger wire and stick down plug hole till it hits piston. SLOWLY turn eng till wire quits moving up.You are now at tdc on the firing (compression) stroke of that cyl. Repeat for each cyl.

|

|

|

|

Post by DanD on Mar 8, 2006 7:38:19 GMT -5

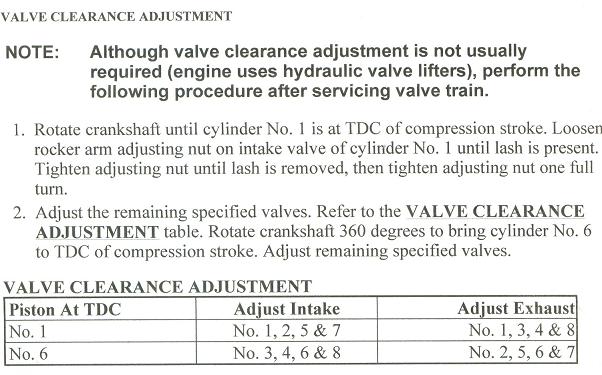

I’m not rereading this whole thread to get caught up on everything but here’s a graph showing when and who to adjust. Dan.  |

|

|

|

305 SBC

Mar 8, 2006 11:28:05 GMT -5

Post by re-tired on Mar 8, 2006 11:28:05 GMT -5

Thanks Dan .I could not find my chart with the adjusting order. So i was trying to go the least tech way to get them done. I have passed the baton. The gentleman from canada has the floor!:0) :0)

|

|

|

|

305 SBC

Mar 8, 2006 19:19:43 GMT -5

Post by DanD on Mar 8, 2006 19:19:43 GMT -5

No you’re doing just fine re-tired and this is me stepping back and letting you have a shot at helping with this problem.

Dan.

|

|

|

|

305 SBC

Mar 12, 2006 11:43:50 GMT -5

Post by kringold on Mar 12, 2006 11:43:50 GMT -5

Here's the update. I broke down and did it the hard way to make sure I got it right. I went cylinder by cylinder and adjusted the rocker arms. In doing so, I backed off the rocker arm nut completely and then pulled out the pushrods, and checked to see if any were bent from that backfire. None were. While I had the nut loose, I allowed a couple minutes for each of the lifters to relax. Then I tightened one full turn per the shop manual. She fired right up, with no problems, that I can tell anyways. I couldn't really hear very well because that backfire, it blew almost the entire rear end of my muffler out. BIG hole. So now I'll be under the car today.

|

|

|

|

305 SBC

May 29, 2019 21:04:02 GMT -5

Post by axikiloyu on May 29, 2019 21:04:02 GMT -5

23 <a href="http://mewkid.net/buy-prednisone/">Prednisone Without Dr Prescription</a> zgq.ynia.venturi.proboards.com.qkc.my mewkid.net/buy-prednisone/

|

|

|

|

305 SBC

May 29, 2019 22:44:34 GMT -5

Post by awzabot on May 29, 2019 22:44:34 GMT -5

|

|